StratoMAX – Coupler Systems Designed for Your Maximum Advantage

Strato’s philosophy is to DO MORE for the FUTURE of RAIL. This starts with our core values of providing quality products, unsurpassed customer service and excellent field support, all of which continue to be critical to our success.

Additionally, other unique advantages of Strato include the following:

We continually invest in new product development that will generate a better return on investment for our customers and support growth for the railroad industry.

Our competence in large casting development enables us to produce the toughest knuckles, couplers and coupler components in the market.

Always pursuing excellence, we continually fatigue test our knuckles and couplers using the same criteria as the AAR. The average fatigue life cycle of our E-knuckle is more than double the AAR requirement and the couplers have yet to fail during our rigorous testing. Based on these extraordinary results, the product line was branded StratoMAX in 2016.

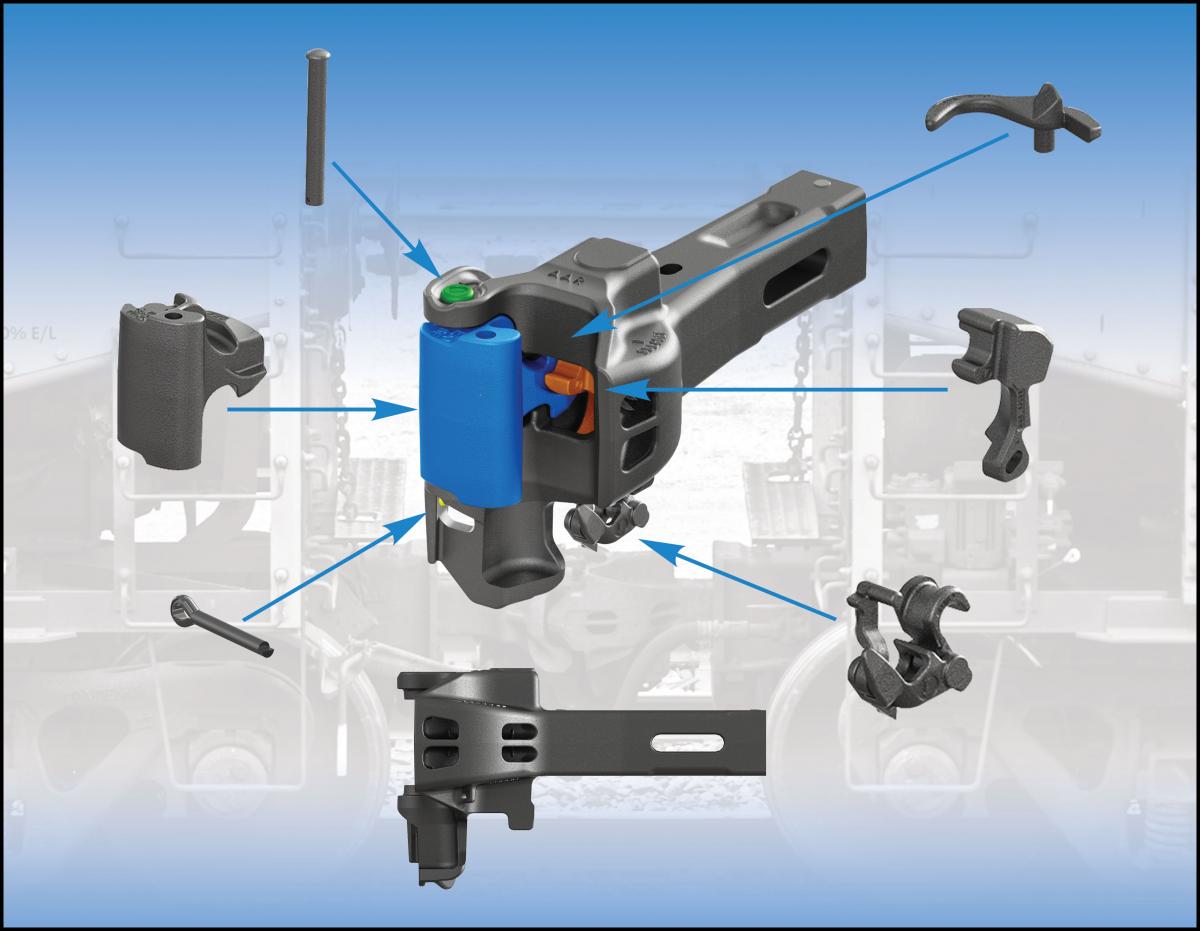

The StratoMAX product line includes superior couplers, knuckles, locks, lock-lift assemblies, knuckle throwers and knuckle pins.

MAXimum Longevity

Strato continues to test our coupling system fatigue life to AAR standards using our massive in-house test equipment aptly named - HERCULES. This state of the art equipment is designed to replicate field conditions and evaluate the fatigue life of our products.

The average fatigue life of our E-knuckle reaches more than double the AAR requirement.

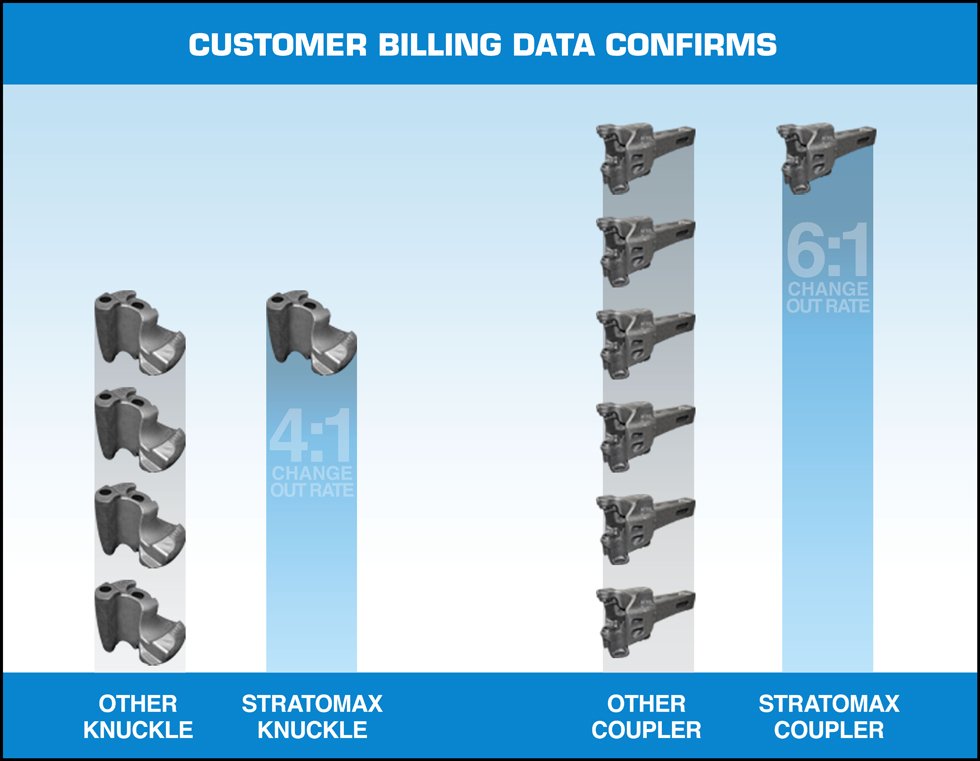

Customer billing data validates substantial maintenance cost savings. When compared to AAR Approved knuckles, the StratoMAX knuckle design was replaced at a ratio of one to four of the others. Couplers achieved similar results – a ratio of one StratoMAX coupler design to six of the others.

MAXimum Interchangeability

Manufacture is designed and controlled in every step of the process to ensure products are delivered to fit.

A dedicated team of engineers formulated the optimal manufacturing strategy including tooling design, metallurgical chemistry, pouring speed, heat treat, quench, gaging and continual inspection processes that guarantee dimensional consistency.

MAXimum Operational Performance

StratoMAX products improve your return on investment. Dimensional accuracy reduces the need for grinding to fit during installation and increased fatigue life keeps the products in service longer.

Benefits include increased velocity, lower labor and product replacement costs.

Availability

Strato’s management team continually optimizes its operations to maximize customer value and implement appropriate stock levels in convenient locations for fast service. StratoMAX products are available from several strategically placed warehouses in North America.

This, coupled with a top-notch team of Account Managers and Product Specialists, enable Strato to deliver a satisfying customer experience each and every time.