Heavy Duty End Hose Straps - Reduce Damage in Railcar Hose Separations

Pressurized end hose separation can create gladhand recoil powerful enough to cause broken hose straps and damage to the railcar.

- Meets S-4006-2008 Standard

- Extra Strength for Longer Life

- Exceeds AAR Standards - Lifts 500 lbs.

- Reduces Maintenance and Replacement Costs

- Cold Temperature Tested

- Reduced Damage

- Double Hook with Locking Tab to Prevent Rotation

- Zinc Plated to Resist Corrosion

- Easy Installation and Adjustment with Gloved Hands

Every time a pressurized end hose separates, planned or unplanned, it throws back the gladhand with great force. The air in the hose acts like a jet engine powering the gladhand.

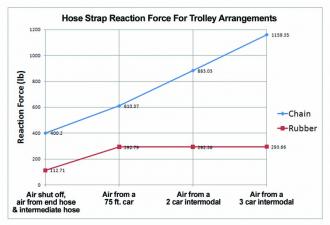

Even with the angle cock closed, up to 400 pounds of force can be generated by just the air in the end hose and intermediate hose, resulting in car damage and broken hose straps.

You can't change the laws of physics. The energy generated from any hose separation must be absorbed by the connecting components.

A rigid strap absorbs no energy, focusing all of the energy on the impact. The force on the chain can be up to four times that of a rubber strap.

A rubber end hose strap stretches to absorb energy, reducing the force levels prior to impact with the car.